Powering Santa’s Workshop

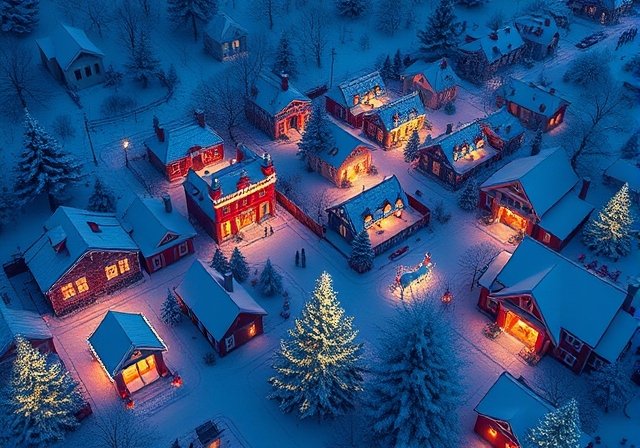

We are at that time of year when people are putting up their trees and setting out milk and biscuits in anticipation of the visit of the man in the big red suit. Christmas is a busy time of year for all, resulting in some of the highest energy consumption periods.

From twinkling Christmas lights to running ovens, and indoor heating, households in the UK use approximately 402,000 megawatt hours (MWh) — or 402 gigawatt hours (GWh) — of electricity. Just 1 GWh is enough to power 876,000 homes for a whole year. However, this is a fraction of the energy used by one of the biggest toy manufacturers in the world.

To help decrease everyone’s carbon footprint on Christmas, we are excited to share that we have signed on Santa and the Claus’ estate to conduct our next set of wind mapping studies. Partnering with Mr Claus and his team, we have conducted an initial wind mapping study and energy audit of his site in his bid to become net zero.

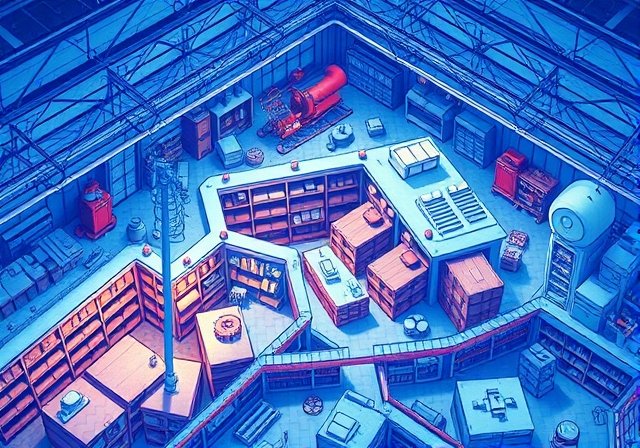

Building and storing 1.2 billion presents annually, Santa is the largest toy manufacturer and distributor globally. His manufacturing and distribution estate spans nearly 5.7 million square metres to accommodate all the work he and his elves do. With such a large estate and tight annual deadlines, his workshop has an annual consumption of 1,250 GWh. Subsequently, Mr Claus’ CO2 footprint is a whopping 603,072 tonnes each year!

Wind analysis & power

Located at the North Pole, Santa’s workshop is located in a region which benefits from nearly 6 months of sun and 6 months of near-total darkness. With solar being only beneficial for half of the year Mr. Claus is seeking to turn to wind power as a year-round solution for his site. Unfortunately, wind turbines would not work across his estate due to the open rotations interfering with the frequent reindeer practice sessions led by Rudolph, and the use of reindeer radar to track their take-off and landing movements. However, the location of his workshop is in a high-wind region suitable for Katrick’s Wind Panels.

Without giving away his top-secret location our team has demonstrated a 76 per cent to a near 100 per cent fit for our technology with annual mean wind speeds ranging from 4 m/s up to 7 m/s on average. This is also seen across 3 sites that are closely located to his North Pole location, including:

Yellow highlighted regions demonstrate a 100% fit of wind speeds for our Wind Panel technology across Greenland (left), Svalbard, Norway (centre), and Ellesmere Island, Canada (right).

With such high annual mean wind speeds on-site, our team has demonstrated that our 1kW industrial Wind Panels can deliver 2,190kWh per year.

To fully power Santa Claus’ toy manufacturing site, Mr Claus will require the installation of 572,400 Wind Panels. However, with population increasing and the introduction of automation services to accommodate toy volume increases, our team recommends 650,000 Wind Panels to deliver 1,424 GWh of carbon-free electricity.

Using modular wind energy devices like our Wind Panel technology, Santa can easily scale his potential energy generation to fit his growing business and energy demands. His location in one of the highest windy regions suits the use of wind technology where solar is limited. Additionally, the use of Katrick’s Wind Panels across his site does not interfere with his use of reindeer radar. Providing a robust solution to help decarbonise his manufacturing activities and putting a bit more green back into Christmas.